Antistatic ESD UHMWPE Plastic Plate From 0.05mm -80mm Thickness

About UHMWPE:

UHMWPE (also known as Ultra High Molecular Weight Polyethylene) Sheet and Rod products are manufactured from the semi-crystalline polyethylene (PE) family. Chinese UHMWPE Sheet and rods' maximum molecular weight can reach to 5 million which has a positive impact on material performance in an abrasive environment.

UHMWPE Advantages:

UHMWPE properties ensure that this plastic material is very light, extremely tough, chemically resistant and has excellent wear resistance.

Key Features:

Applications:

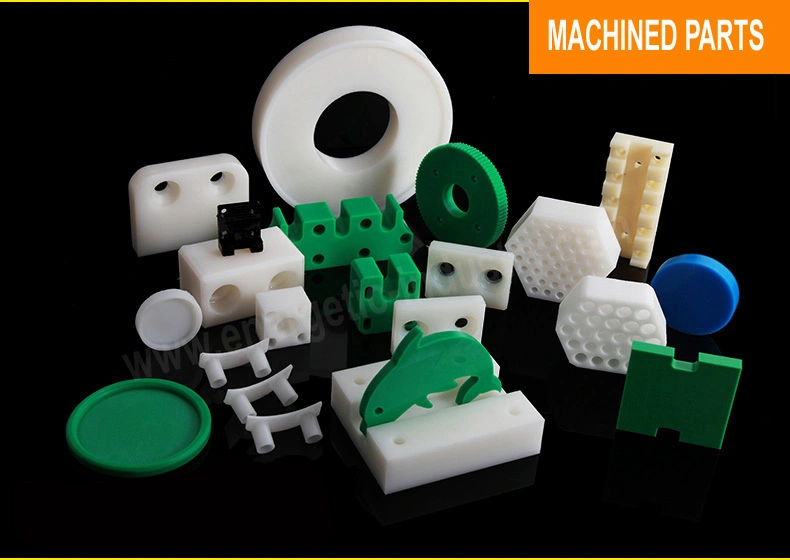

UHMWPE Products:

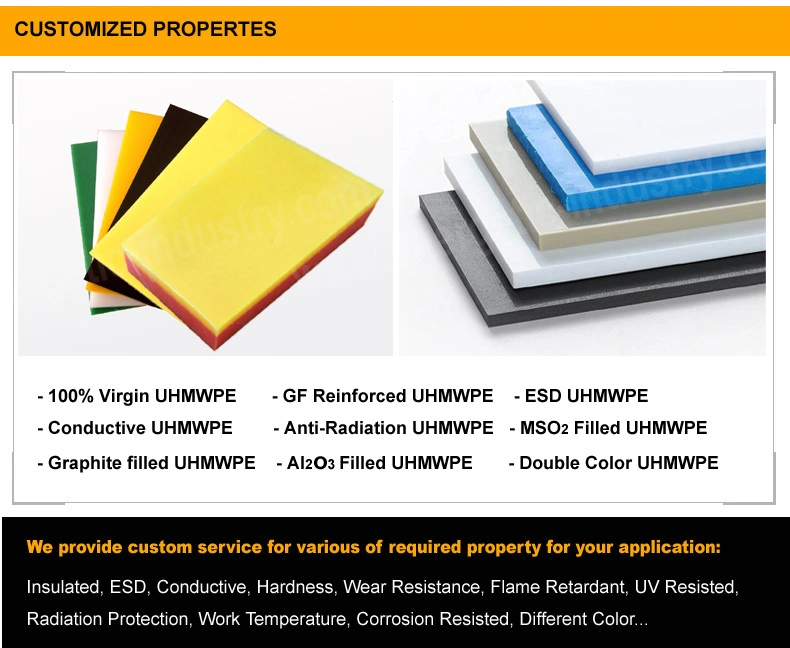

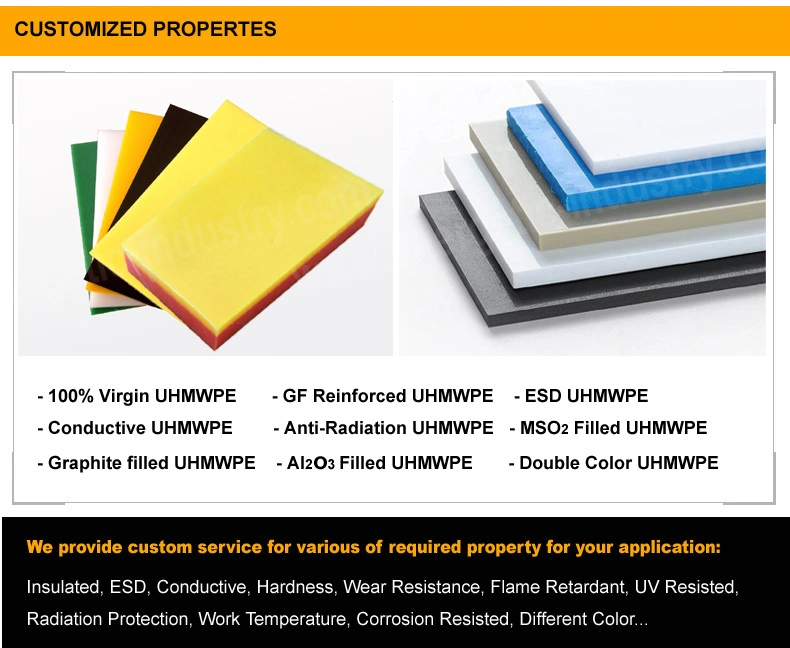

- Extruded or Molded UHMWPE: Unfilled, natural white

- ESD UHMWPE:

Anti-static properties of PE-UHMW are often required with high line speeds and conveying rates. ESD UHMWPE meets these requirements. Anti-static properties are achieved by incorporating efficient carbon black types.

- Modified UHMWPE:

To modify UHMWPE make heavy duty ground mats, it can be used to provide temporary access and ground protection over and around soft nd sensitive areas.

- Boron Carbide filled UHMWPE

UHMWPE containing 5% or 10% boron polyethylene board was prepared by hot pressing process. Boron carbide/UHMWPE composite sheet is use for neutron shielding. Boron carbide powder was stirred by high speed stirring, kneading, plasticizing and hot pressing in the UHMWPE board. It was a new type of composite shielding material.

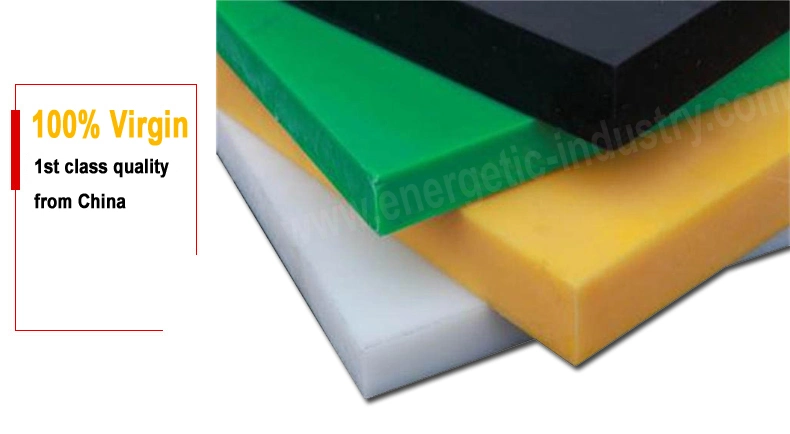

| Trade names: | Ultra High Molecular Weight Polyethylene/UHMWPE |

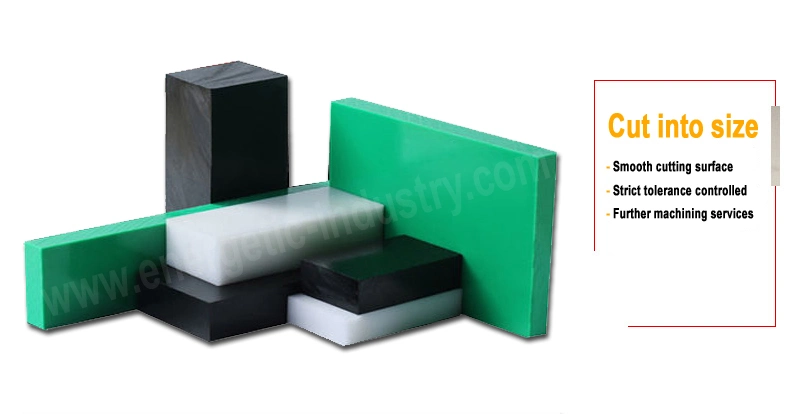

| Available Shapes: | Sheets, Rods, Plates |

| Color: | Natural White, Black, Other |

| Sheets Thickness: | 0.05mm ~ 300mm |

| Size: | 2000mm x 1000mm, 3000mm x 1500mm, 5000mm x 1300mm, 4700mm x 1200mm, 4500mm x 2000mm |

| Rods Diameter: | 2.0mm ~ 250mm |

| Length: | 1000mm |

About UHMWPE:

UHMWPE (also known as Ultra High Molecular Weight Polyethylene) Sheet and Rod products are manufactured from the semi-crystalline polyethylene (PE) family. Chinese UHMWPE Sheet and rods' maximum molecular weight can reach to 5 million which has a positive impact on material performance in an abrasive environment.

UHMWPE Advantages:

UHMWPE properties ensure that this plastic material is very light, extremely tough, chemically resistant and has excellent wear resistance.

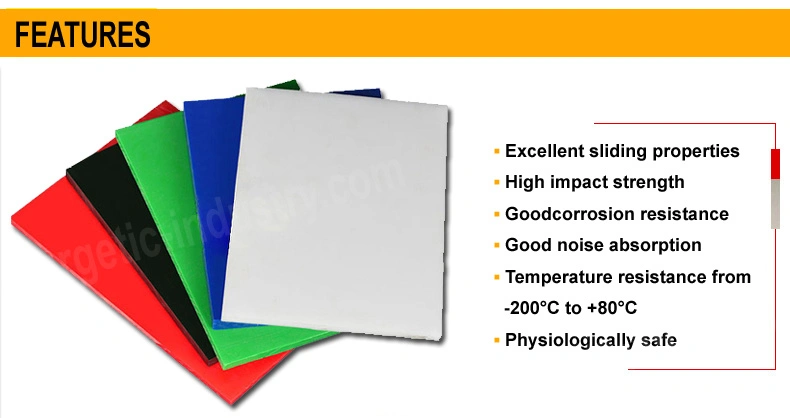

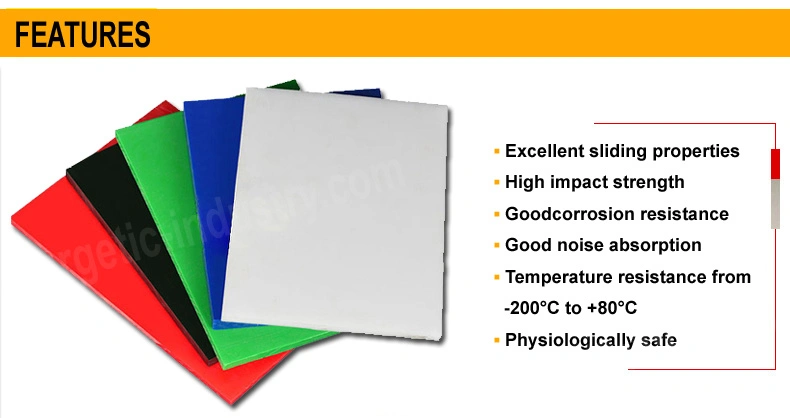

Key Features:

- Excellent sliding properties

- High wear resistance

- High impact strength

- Very good chemical and corrosion resistance

- Good noise absorption

- Anti-adhesive

- High energy absorption capacity and high stress rates

- Temperature resistance from -200°C to +80°C

- Physiologically safe

Applications:

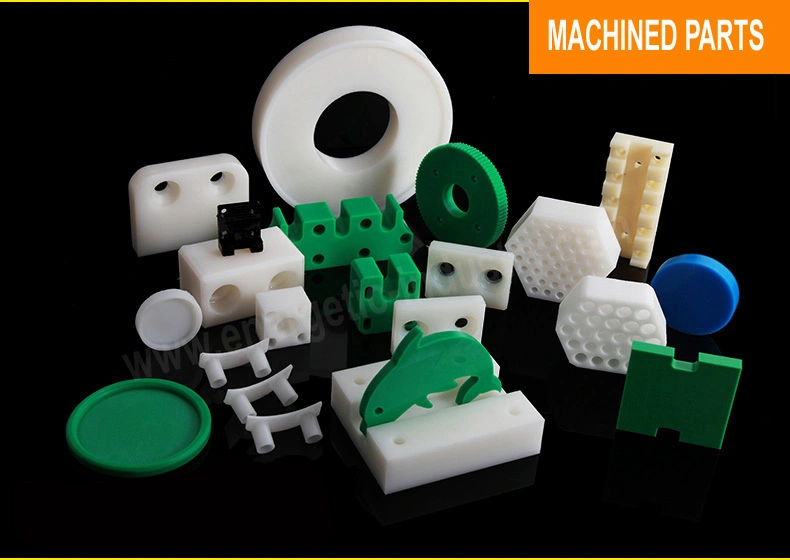

- Chemical Engineering: Corrosion and wear resistance mechanical parts

- Thermal power: coal handling, storage of coal, warehousing chute lining

- Coal processing: sieve plate, filter, U-underground coal chute

- Concrete: cement raw and finished product silo lining

- Grain: food storage or chute lining

- Mining: sieve plate, chute linings, wear anti-bonding part

- Food industry: star-shaped wheel, transmission timing bottle screw, bearings, guide rollers, guides, slide blocks, etc.

UHMWPE Products:

- Extruded or Molded UHMWPE: Unfilled, natural white

- ESD UHMWPE:

Anti-static properties of PE-UHMW are often required with high line speeds and conveying rates. ESD UHMWPE meets these requirements. Anti-static properties are achieved by incorporating efficient carbon black types.

- Modified UHMWPE:

To modify UHMWPE make heavy duty ground mats, it can be used to provide temporary access and ground protection over and around soft nd sensitive areas.

- Boron Carbide filled UHMWPE

UHMWPE containing 5% or 10% boron polyethylene board was prepared by hot pressing process. Boron carbide/UHMWPE composite sheet is use for neutron shielding. Boron carbide powder was stirred by high speed stirring, kneading, plasticizing and hot pressing in the UHMWPE board. It was a new type of composite shielding material.